站点地图

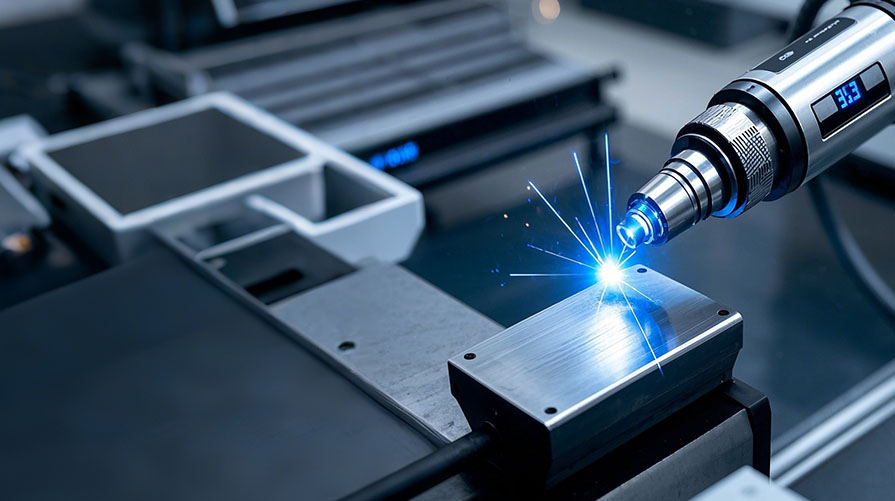

The core of laser cladding process parameters is the balance between energy control and material interaction, which mainly involves the following key elements:

1. Energy input

Laser power and spot morphology determine the energy density. The power directly affects the depth of the molten pool and the degree of material melting, while the shape and size of the spot (such as circular or rectangular) regulate the energy distribution, affecting the width and surface quality of the cladding layer.

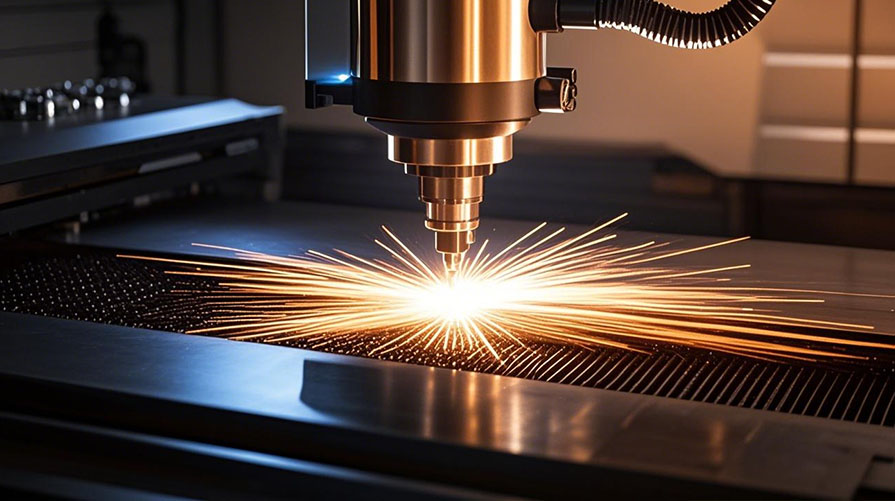

2. Dynamic process

The cladding speed determines the heating time and cooling rate of the material, too fast may lead to non-fusion, and too slow will increase the risk of thermal deformation. The powder feeding speed needs to match the laser energy to ensure that the powder is fully melted and a uniform cladding layer is formed.

3. Spatial relationship

The defocusing amount and processing distance affect the beam focusing effect and powder transmission efficiency, and an appropriate distance should be maintained to avoid optical path interference or powder dispersion. Lap ratio optimizes surface roughness through the control of overlapping areas, but too much lap can cause uneven organization.

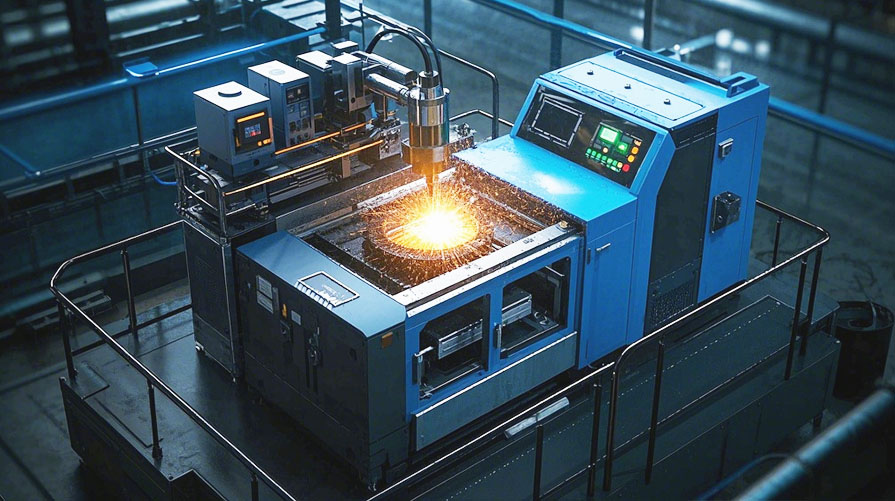

4. Auxiliary control

The protective gas is used to isolate the oxidizing environment, and the pressure needs to be stable to form an effective gas curtain. Preheating and post-treatment can adjust the thermal stress distribution and reduce the crack tendency.

There are complex coupling effects between parameters, for example, high power with appropriate speed can reduce porosity, and the matching of spot size and speed directly affects the dilution rate. Modern technology often optimizes the parameter combination by comprehensive indexes such as specific energy (energy input per unit area), and predicts the performance of cladding layer by simulation technology.

This technology is widely used in the high-end manufacturing field, through the surface strengthening to achieve material performance upgrade, both efficient repair and green manufacturing properties.

0 条评论

网友评论仅供其表达个人看法,并不表明本站立场。