Site Map

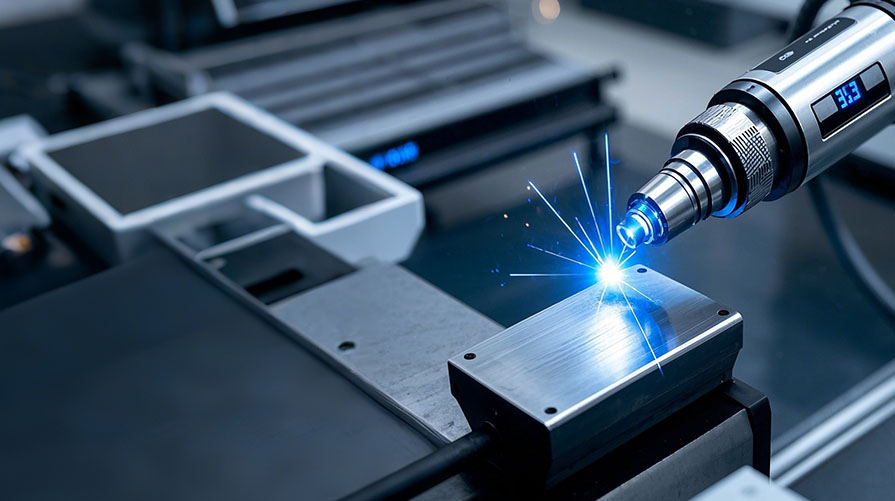

Laser cladding is an advanced technology for surface modification or repair of materials by means of high energy laser beams.

Its core principle is: using the high energy density of the laser beam, the selected metal or ceramic powder and the thin layer of the substrate surface are melted at the same time to form a metallurgical cladding layer, which significantly improves the wear resistance, corrosion resistance, high temperature resistance and other properties of the substrate.

Technical core steps

Energy focusing: The high-energy laser beam focuses on the surface of the substrate, instantly raising the local temperature above the melting point of the material to form a melt pool.

Material fusion: By synchronous powder delivery or preset powder, the cladding material (such as nickel base, cobalt base alloy, tungsten carbide, etc.) is injected into the melt pool and fully mixed with the thin layer of the substrate melting.

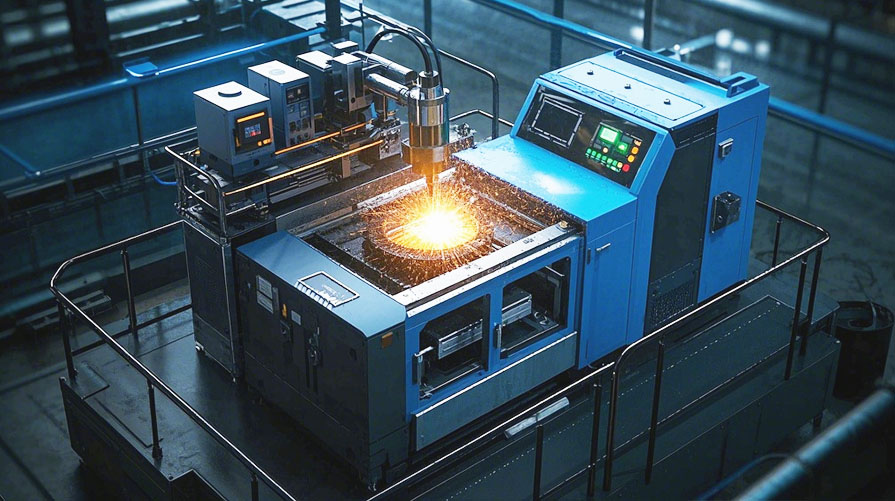

Rapid solidification: After the laser beam is moved, the melt pool is rapidly cooled and solidified to form a cladding layer closely combined with the substrate, with a low dilution rate (usually < 10%) and dense organization.

Technical advantages

Metallurgical bonding: the cladding layer forms chemical bonding with the substrate, which has high bonding strength and is not easy to fall off.

Low heat affected area: laser energy is highly concentrated, the thermal deformation of the substrate is small, suitable for precision parts repair.

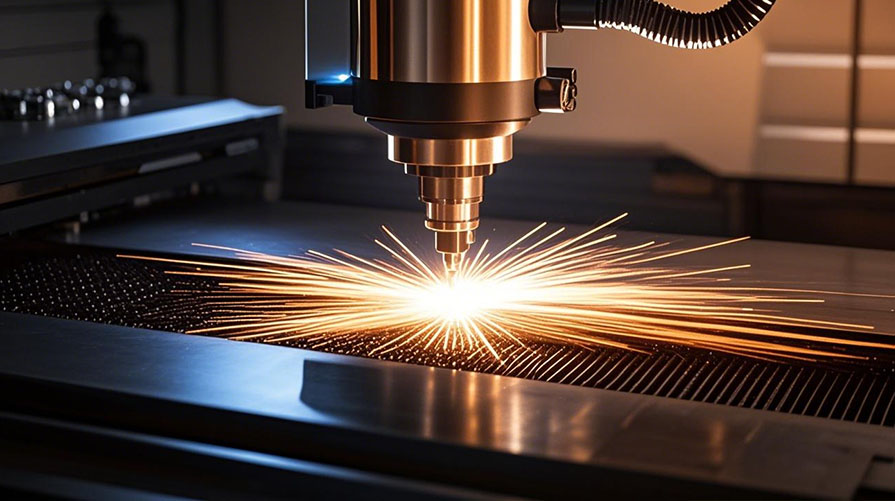

Material compatibility: a variety of alloys or composite materials can be selected to meet the needs of different working conditions.

Green and efficient: no subsequent heat treatment, high powder utilization, in line with environmental requirements.

Typical applications

Widely used in aerospace, energy, automotive, mold and other fields, such as repairing turbine blades, rolls, gears, or strengthening the surface properties of key components such as cutting tools and piston rods.

Laser cladding achieves accurate control of material properties through the physical process of "local melting - rapid solidification", and has become an indispensable surface engineering technology in modern industry.

0 Reactions

We provide Netfriend Comment for people express their own opinion,it doesn't means we agree with their view,and we do not have the responsibility to testify what they said.