Site Map

1.Laser cladding and laser melting are two surface treatment technologies based on laser energy, and their core differences are reflected in the way materials interact and the process objectives.

The following three aspects of technical principle, process characteristics and application scenarios are analyzed:

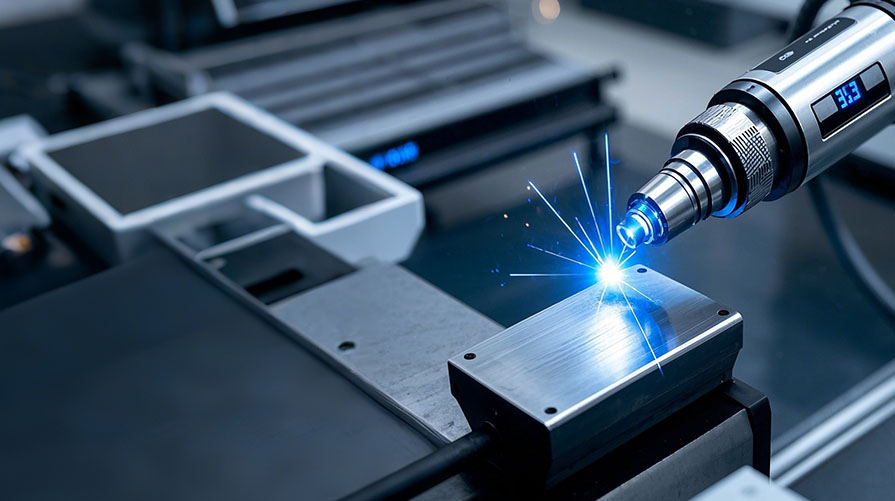

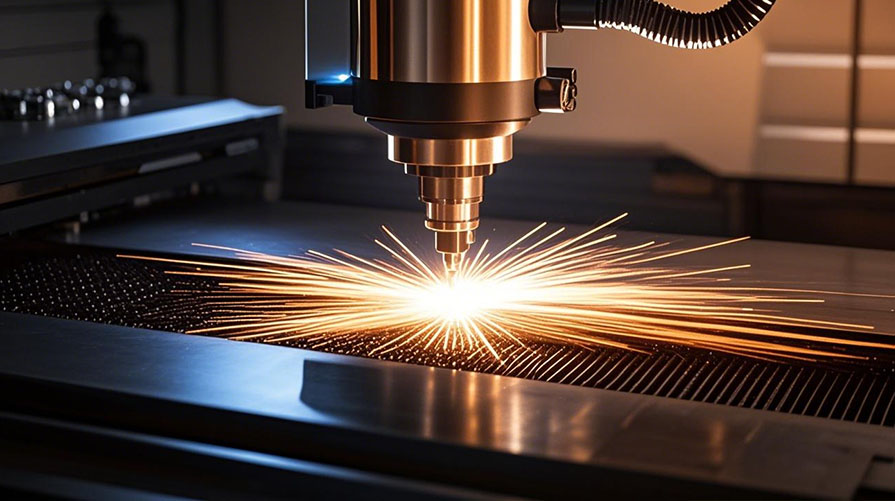

Laser cladding is to melt the pre-placed or synchronously transported alloy powder and the thin layer on the surface of the matrix through a high energy laser beam to form a new coating that is combined with the matrix metallurgy. This process involves material addition with interfacial metallurgical reactions, such as cladding of wear-resistant alloys on the surface of worn parts to restore size and improve performance. Laser melting directly uses the laser beam to irradiate the surface of the matrix to make it freeze after local rapid melting, and only changes the structure of the matrix itself without introducing foreign materials. For example, the melting treatment of the mold surface can refine the grain and improve the hardness.

2. Process characteristics comparison material participatory laser cladding needs to add powder or wire and other external materials, coating composition can be flexibly designed; Laser melting only depends on the material of the matrix itself, and the properties are optimized through the microstructure phase change. The energy of laser cladding needs to melt the additive material and the substrate surface at the same time, the melting depth is usually deep (up to millimeters), and the dilution rate (the proportion of the substrate material mixed with the coating) can be controlled by parameters. The energy of laser melting mainly acts on the surface of the matrix, and the melting depth is shallow to avoid excessive heat influence. Microstructure characteristics Laser cladding may form fine crystal, amorphous or intermetallic compound structure due to rapid solidification, and the hardness and wear resistance of the coating are significantly improved. Laser melting refines the matrix grains by chilling, forming uniform and dense as-cast structure and increasing hardness. Process complexity Laser cladding requires precise control of powder delivery speed, spot energy distribution and other parameters to ensure coating uniformity and bonding strength. Laser melting parameters are relatively simple, mainly concerned with the influence of power density and scanning speed on the dynamics of molten pool.

3. Application scenario differentiation

Laser cladding is suitable for the following scenarios:

Wear repair: such as aircraft engine blades, petrochemical valves and other parts of the size recovery and performance strengthening.

Surface modification: coating corrosion-resistant alloy on the surface of ordinary steel, or preparing high-entropy alloy gradient coating on the surface of aluminum alloy.

Additive manufacturing: Direct fabrication of complex structures by layer by layer cladding.

Typical applications of laser melting include:

Mold strengthening: improve the surface hardness and fatigue resistance of injection mold and stamping die.

Corrosion resistance treatment: Form a dense oxide layer on the surface of stainless steel to enhance corrosion resistance.

Local repair: micro melting treatment of gear tooth surface, journal and other local areas to improve wear resistance.

4.The difficulty of laser cladding is material-process matching, which needs to balance dilution rate and coating performance, while controlling defects such as pores and cracks; Laser melting needs to avoid grain coarsening or matrix deformation caused by overheating, especially when dealing with thin-walled parts, the energy input needs to be precisely regulated. Both of them rely on dynamic cooling control to achieve microstructure optimization through rapid heating and cooling, but laser cladding may produce greater thermal stress due to material heterogeneity.

5. Technology development trend Laser cladding is developing in the direction of multi-material composite and intelligent control, such as using gradient coating design to improve thermal shock resistance, or adjusting parameters in real time through AI algorithm; Laser melting is combined with multi-field coupling techniques, such as the introduction of ultrasonic vibration to refine grains, or in conjunction with chemical treatment to improve surface properties.

In short, the essential difference between laser cladding and laser melting is whether external materials are introduced, the former focuses on performance upgrading and repair, and the latter focuses on matrix self-strengthening. The two are complementary in the industrial field and jointly promote the development of laser surface treatment technology.

0 Reactions

We provide Netfriend Comment for people express their own opinion,it doesn't means we agree with their view,and we do not have the responsibility to testify what they said.